3-D printer opens options for science students

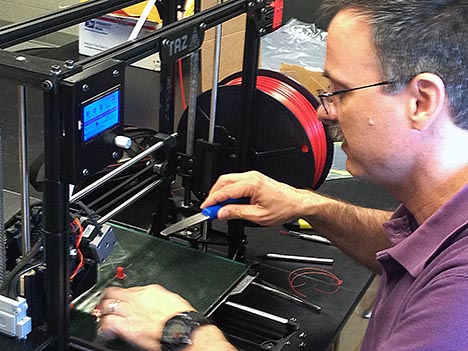

Associate Professor Tim Duman removes a test object from the new 3-D printer in the Department of Physics & Earth-Space Sciences.

Associate Professor Tim Duman removes a test object from the new 3-D printer in the Department of Physics & Earth-Space Sciences.

It seems like magic: Design a model on your computer, and a fancy machine squirts it out as a three-dimensional object, right here in the physical universe.

This is the new frontier of 3-D printing, and some technology acquired this month by UIndy’s Department of Physics & Earth-Space Sciences promises to expand possibilities for students and their laboratory work, especially in physics and engineering courses.

Traditionally, Associate Professor Tim Duman says, when specialty components and enclosures are needed for experiments, students have fabricated the items from various combinations of wood, metal, cardboard, polystyrene and other materials. The possibilities are limited, and the process can be time-consuming, messy and even dangerous if power tools are involved.

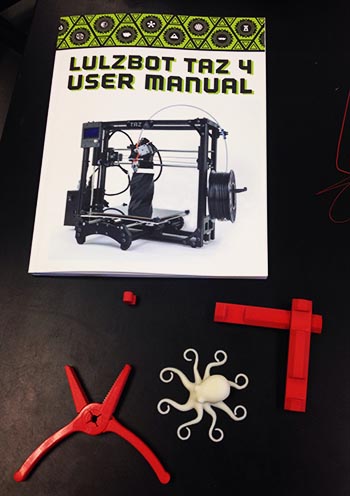

Enter the LulzBot TAZ 4 desktop 3-D printer, a product of Colorado-based open source hardware company Aleph Objects Inc. The new machine can produce items in plastic, nylon and even exotic materials like wood. Its printing volume of nearly 12 by 11 by 10 inches allows for some fairly large objects.

“Now I can say, if you can design it and it fits in this space, we can have it,” Dr. Duman says.

The capability lends itself to physics courses in which students need specialty parts for rocket tests, meteorology and astronomy courses that involve self-contained high-altitude balloon experiments, and engineering courses in computer-aided design and testing. The simple fact of being able to produce physical models of virtual designs can help students stay engaged in their coursework, says department chair and Associate Professor Steve Spicklemire.

“We’re trying to connect real-world, hands-on stuff with high-level theory,” Dr. Spicklemire says. “I’m planning to use this extensively.”

The printer can be connected to a laptop or controlled simply by plugging in an SD memory card containing the design. The printing material is purchased in spools of thin filament. So far, the faculty have been experimenting with Lego-like ABS plastic, in a hue that looks a lot like UIndy red.

“That’s the reason I bought this color,” Duman says. “The other spool is gray.”